- Home

- Blog

- Under Floor Heating

- How to Install Under Floor Insulation

How to Install Under Floor Insulation

Robust insulation is vital for the energy efficiency of homes around the world. According to The Greenage, older homes can lose up to 10% of the heat produced through poorly insulated flooring. Over time, this can lead to considerably higher energy costs than expected if proper underfloor insulation is in place.

The process of installing underfloor insulation may seem like a daunting one. Still, there are several options for installations and underfloor insulation products that are cost-effective without the need to hire professionals. Each house and situation is slightly different, so you will need to determine which solution is best for you ahead of time.

This article will explore the options for underfloor insulation you may wish to consider as well as the steps needed to ensure the installation will result in reduced energy bills and a warmer home. It will also provide a summary of the most effective types of underfloor insulation materials.

Do I Need to Insulate?

Developers will build most modern homes with the best underfloor insulation available in terms of energy-efficient solutions and long-lasting materials such as polystyrene boards.

However, many older houses were often built with suspended timber floors. This was because flooring placed directly onto the ground would often experience moisture and rot in the floorboards. By utilizing suspended floors, ventilation could pass beneath the flooring via sub-floor vents, keeping things nice and dry.

The disadvantage to this was that cold air could rise through the flooring, leading to a considerable reduction in the temperature inside the house.

Similarly, houses with flooring made from a concrete slab can suffer from poor insulation. However, underfloor insulation installation is often put in place first before the concrete is poured, mitigating the issue.

It is worth investigating precisely the type of flooring you have before investing in updating your underfloor insulation.

Why Underfloor Insulation is Important

There are several reasons why having the best underfloor insulation available is vital for your house.

Improved Thermal Efficiency

Installing underfloor insulation helps to improve the overall thermal performance of your house. High thermal efficiency will usually reduce heat loss and retain heat for much longer periods.

Lower Energy Costs

If your thermal performance is at a high level and your insulation installations can help reduce heat loss, there will be less need to turn on the central heating during the colder months. This will lead to an overall reduction in your energy bills.

Effective Vapour Barrier

A timber floor can often be vulnerable to moisture. Effective underfloor insulation can help create a vapour barrier that can increase moisture resistance and maintain the integrity of the floor materials for a more extended period.

Protects Piping

In colder climates, pipes that run beneath the floor are often at risk of damage from freezing and cracking. A layer of underfloor insulation can help protect this piping.

Insulating a Suspended Timber Floor

A suspended timber floor is defined as a floor space that sits upon wooden floor joists to allow for ventilation. They can typically be insulated in one of two ways depending on the type of access you have to the floorboards.

Access from Underneath

Logistically, this is the most straightforward scenario to install underfloor insulation yourself. If your house has a cellar or access to an underground space, you can install a rigid insulation panel from beneath and fix it in place using underfloor insulation batts.

It is crucial to ensure that the measurements on the panels are accurate. If the panels are too small, i.e., they don't form to the perimeter of the floor joists, there is still the chance that a draught will be able to escape through the gaps around the panels.

Access from Floor Level

If you do not have access to the floor from beneath, you will need to install your underfloor insulation from the floor level.

It may not be necessary to fully remove the floorboards if you only intend to use a sealant or caulking to fill in any gaps for draught-proofing purposes.

However, if it is clear that a more substantive insulation process is required, you will need to remove all furniture from the room and lift the timber floor boards out of place to gain access to the joists.

Once this has been done, you will need to spread a net over the entire floor space, ensuring that there is slack between the joists. The insulation products will sit within these net cavities.

Once the net is in place, you can begin to fill the gaps with whichever insulating material you have chosen. The material should run parallel to the joists and be approximately the same width.

Once the netting has been filled, the floorboards need to be fitted back in place.

Insulating Solid Floors

Many modern homes are built with solid floors with underfloor insulation already in place. However, if you feel additional insulation is required, it is still possible to install it retrospectively, usually in the form of polyester underfloor insulation or polystyrene foam boards.

Before you place the insulating boards down, you will need to make sure that you apply a damp-proof membrane to ensure the underfloor insulation is protected from moisture. You should also look to place chipboard over your insulation boards to help protect them.

Types of Underfloor Insulation Materials

There are several types of underfloor insulation materials you may wish to choose from.

Fibreglass

One of the best underfloor insulation materials is fibreglass, consisting of fine glass fibres made from molten glass. Fibreglass batts are highly effective as insulation material due to the thousands of tiny air pockets that trap air and disrupt heat flow. Recycled glass materials can also be used within insulation panels.

Mineral Wool

These typically come in two forms - rock wool and slag wool. Both are artificial materials, with rock wool consisting of natural substances such as basalt and slag wool consisting of waste matter from a molten metal called slag.

Natural Fibres

Several types of natural fibres are used for underfloor insulation products. Each type will generally have a high R-value and will be safe to install, making them some of the best insulation products available.

Cotton

Concerning insulation, cotton is made up mostly of recycled cotton though up to 15% of the composition is plastic fibres that have been treated with flame-resistant substances.

Sheep's Wool

Sheep's wool is treated with chemicals such as borate to best resist mold and fire in much the same way cotton is.

Straw

Straw is perhaps not the first material a person might think of concerning modern homes. Still, it is possible to create reliable and effective insulation products by fusing straw into boards. Straw-treated panels and boards are also effective for sound absorption and can be used to reduce reverberation and improve acoustic performance.

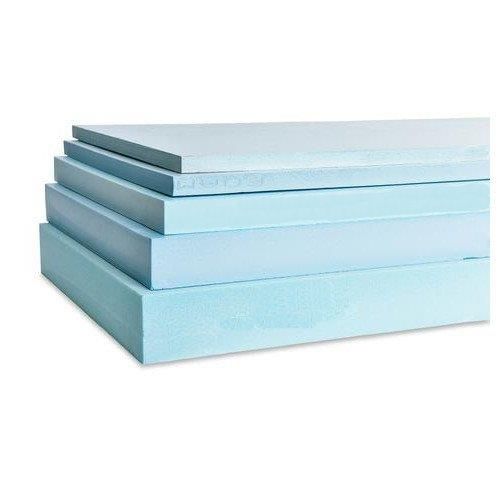

Polystyrene

Polystyrene is a highly versatile material commonly used for thermal insulation purposes. Typically it is either installed in the form of a foam board or as small beads in a loose-fill installation. This bead formation often forms part of a concrete insulation installation.

Final Thoughts

Floor insulation is an essential feature of all modern homes, but upgrading your insulation structures within an existing home is possible. Whether you choose to install the installation yourself or seek assistance from professional installation experts, you will soon reap the benefits of increased energy efficiency and reduced costs.

Here at Trade Warehouse, we aim to offer a 'one-stop shop for all your DIY and home improvement needs. Since 2010 we have provided our customers with everything they need to help create their perfect homes.

If we do not have the product you were searching for, contact us today, and we will do our best to secure it for you at a competitive price!